Artificial Bone Made of Wood

A new procedure to turn blocks of wood into artificial bones has been developed by Italian scientists (in Instituto Di Scienza E Techologia Dei Materiali Ceramici), who plan to implant them into large animals, and eventually humans.

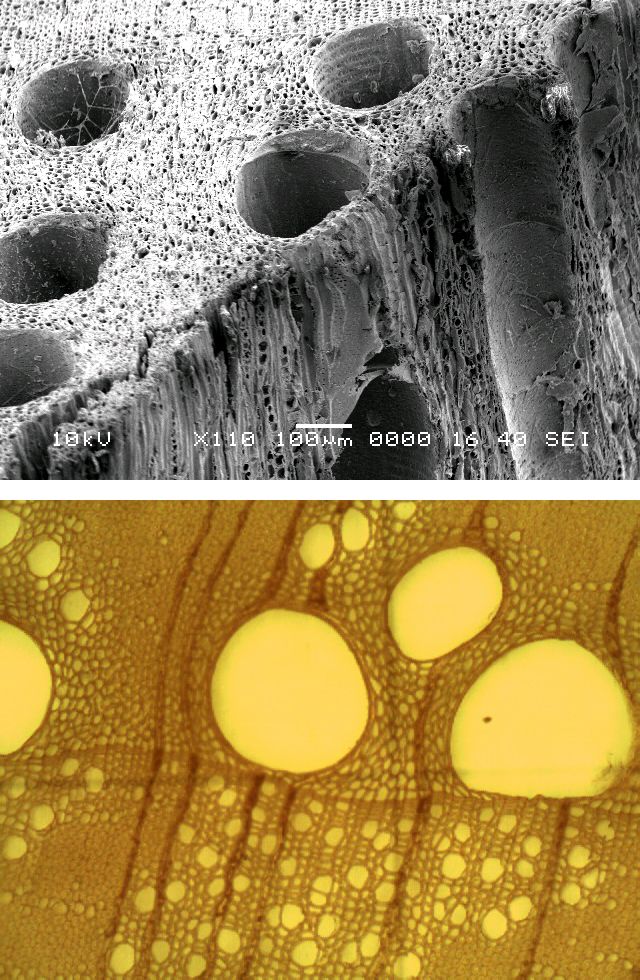

They say the wood-derived bone substitute should allow live bones to heal faster and more securely after a break than currently available implants.Wood closely resembles the physical structure of natural bone, which is very difficult to reproduce with conventional processing technology.

To create the bone substitute, a block of wood, red oak, is heated until all that remains is pure carbon, which is basically charcoal. Then, they should spray calcium over the carbon, creating calcium carbide. Additional chemical and physical steps convert the calcium carbide into carbonated hydroxyapatite, which can then be implanted and serves as the artificial bone.hardwood microstructure

cancellous bone microstructure